Meet the Experts scrap jewellery

scrap jewellery

Although the price of gold is down, it is still significantly higher than it was pre 2008. Current prices of around £24 per gram make it worthwhile for scrap buyers to ensure that they sell carefully too, obtaining the best price for the metal.

However, the first and most obvious response is to assess the items submitted for scrap. The high volume scrapping of the past few years can tell a tale of some wonderful pieces of craftsmanship, of high intrinsic value, which have been lost to the furnace because no one thought to rescue them. The irony is that the provenance, workmanship, brand or rarity of some items makes them far more valuable than their scrap price but people do not always invest the time or money to assess them.

Expertise is available to help with this. The independent SafeGuard Valuation service at Assay Office Birmingham will assess an item and provide a valuation at its current average retail price as guidance. The AnchorCert GemLab, also a division of the Assay Office will authenticate the gemstones by way of straightforward identification or by grading their quality. Both services provide an independent assessment of the piece which can then be resold separately, delivering a return much higher than scrap value.

In order to obtain the best possible price for scrap sellers need to fully understand the nature of what they are selling. There are some general misconceptions and practices that can lead to underpayment, whereby the business selling the scrap does not fully benefit from the value of precious metal it contains. This can be the result of three different issues: the assumed precious metal composition of the items scrapped, the melting process and the assay process. Attention to detail is crucial as is experience and expertise if the customer is to be given the most accurate results possible.

The UK’s rigorous independent hallmarking system is a huge benefit to the scrap market as it ensures that if a customer is scrapping hallmarked items their precious metal composition is guaranteed. One of the big surprises in America during the recent ‘old gold’ rush has been that, in the absence of a controlled hallmarking system, the retailer who originally sold an item as 14K may only buy it back as 10k as they know it to be significantly under-carated. This has led to some interesting conversations and has done nothing for the reputation of the trade.

In the UK the situation is quite the opposite. The Hallmarking Act does not allow any negative tolerance which means that all components of an item must meet at least the minimum requirement, for example 9ct gold must be at least 375 parts per thousand. In order to ensure items pass assay prior to hallmarking, manufacturers will therefore err on the positive and the average fineness of each standard being hallmarked is actually slightly above the prescribed level.

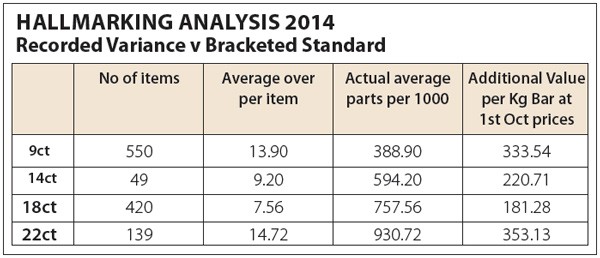

To try to quantify this, we analysed the XRF results from three of the X-Ray Fluorescence units used for assaying goods prior to hallmarking. The results showed that during August 2014 the average fineness of 9ct gold hallmarked was 388.9 parts per thousand as opposed to the 375 required legally. On current prices this would make a difference of £333 per kilogram to the value of the ‘9ct’ gold scrap.

This figure was derived from 550 samples, a reasonable quantity to give a realistic average. The actual fineness of 14ct, 18ct and 22ct are equally over-delivered (as detailed in the attached chart). These figures clearly demonstrate the benefit of having scrap independently melted and assayed before selling the bar, to ensure that the buyer pays the appropriate price for the precious metal content. The extra cost involved – around £60 - will be recovered at least three fold and sometimes much more.

In order to obtain an accurate result from the melt it is important that the material is treated correctly to extract all the precious metal and create a homogenous bar. This requires experience, expertise and sometimes patience.

No two melts are the same and an initial assessment by the melter will identify the level of non precious metals present including items that may contain iron, or sometimes even pennies to add to the weight of the product. This will determine the temperature at which the melt is initiated, the addition of the appropriate melting flux and the percentage of precious metal contained in the melt, providing an important ‘sanity check’ when the bar is assayed.

No two melts are the same and an initial assessment by the melter will identify the level of non precious metals present including items that may contain iron, or sometimes even pennies to add to the weight of the product. This will determine the temperature at which the melt is initiated, the addition of the appropriate melting flux and the percentage of precious metal contained in the melt, providing an important ‘sanity check’ when the bar is assayed.

Batches of scrap containing high quantities of non precious materials e.g. stones and glass, or functional components such as steel springs and internal watch workings may have to be melted twice, sometimes three times, in order to fully separate the precious from the non precious metal.

The experienced melter will raise the temperature of the melt slowly, according to its content, in order to skim off the non precious metal elements as much as possible. All melts have flux added to assist the binding of the metals, absorb some of the unwanted elements and assist the flow, leaving both the bar and the melting ‘pot’ cleaner. These factors improve the recovery rate of precious metal from the melt.

In order to obtain an accurate assay result it is crucial that the sample tested is homogeneous and representative of the whole bar. While some melters will create the bar and then test samples drilled from each end of it, the Analytical Laboratory at the Assay Office prefer to take a dip sample while the metal is still molten. This is extracted from the centre of the molten metal, while it is being stirred, to ensure it is homogenous and to provide the most accurate result. A narrow glass tube is dipped into the molten metal in the furnace to capture the sample and is then smashed after cooling to release the sample for assaying. The bar and the dip sample will be tested by XRF to double check they are consistent, then the dip sample will be assayed by the cupellation method, to give a highly accurate result. Once the bar has the benefit of an independent melt and assay report, the seller can offer it around to gain the highest price. Buyers will quote confidently knowing that the precious metal content of the bar is as stated. The relatively small additional cost of an independent melt and assay will be well rewarded by a significantly higher value outcome than some other routes to market would offer. Once the transaction has been completed the Laboratory will facilitate the transfer of the bar to the buyer, making it a straightforward, convenient and lucrative process.

Your item has been added to the basket

You need to create an account, or login before you can add this item to your basket.

Tim joined the Assay offi ce in January 2005 as account manager for the Analytical Laboratory. Having worked in the precious metal industry for most of his career, including Engelhard and AMi Doduco, Tim has a wide knowledge of the precious metal and fashion jewellery industry. His current role is raising the awareness of the full extent and scope of services offered by Assay office Birmingham.

Tim joined the Assay offi ce in January 2005 as account manager for the Analytical Laboratory. Having worked in the precious metal industry for most of his career, including Engelhard and AMi Doduco, Tim has a wide knowledge of the precious metal and fashion jewellery industry. His current role is raising the awareness of the full extent and scope of services offered by Assay office Birmingham.