Plating, Porosity & Hardness

Plating, Porosity & Hardness Testing

Plating Thickness

Non Destructive Plating Thickness Determination

This test is carried out using X-Ray Fluorescence analysis. The test can establish plating specifications, for example:

- Layer thickness

- Composition

- Material Conformity

- Articles of all shapes and sizes in both precious and non precious metal coatings on metallic and non-metallic substrates can be measured.

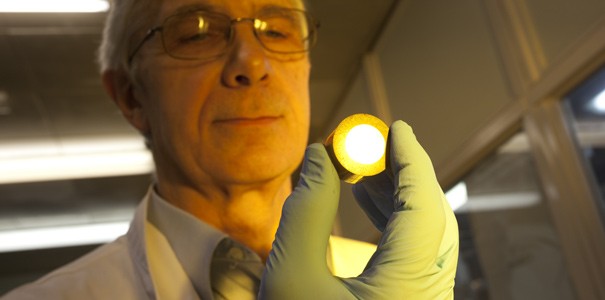

Destructive Plating Thickness Determination

This test is used to determine the thickness of plated layers. It is routinely completed by taking a cross section of an article, mounting it in resin and then grinding and polishing it. The cross section is then examined using an optical microscope and the plating thicknesses measured in micrometers using a video Calder on a monitor screen. Photographs can also be used. Such methods are also used to examine and record suspect hallmarks.

When submitting an item for plating thickness, please include a copy of the plating spec (what the different plating layers are) with your items and the test request form. Failure to submit a plating spec with the item will result in a higher charge for the customer.

Plating Wear

During use and storage, jewellery may be subjected to scuffing by contact with foreign materials, this in turn can lead to a degradation in the plating.

AnchorCert Analytical has developed an accelerated test which simulates 2 years of use, which is designed to ascertain the degree to which a coating/plating, can withstand such conditions and how it will perform during service.

The test results are reported as follows -

- No change – no abrasion ( 0%-20% degradation in plating);

- Slight change – barely perceptible abrasion (21% to 40% degradation in plating);

- Moderate change – obvious signs of abrasion ( 41% - 60% degradation in plating);

- Distinct change – distinct change ( 61% - 80% degradation in plating);

- Severe change – coating is severely marred or removed (81% - 100% degradation).

No change, slight change and moderate change are categorised as 'acceptable'. However, for the other two categories a view may be taken depending upon the type of item and its intended use and suitability. In some cases Customers may conclude that a severe change in plating wear is acceptable to their product, especially if the item is of a very low cost.

The turnaround time for this service is within 5 working days.

Porosity

This test gives an indication of the quality of the gold, rhodium or platinum coating on a base metal alloy. Its purpose is to highlight any corrosion of the base metal alloy in areas where there any inconsistencies in the surface coating.

The turnaround time for this service is within 5 working days.

Hardness Testing

AnchorCert Analytical is fully equipped to carry out Hardness Vickers testing to determine the hardness of a metal item.

AnchorCert Analytical uses method BS EN ISO 6507-1 to help determine the value of hardness according to the Hardness Vickers Chart.

The lower the value, the softer the metal is.

The turnaround time for this service is within 5 working days.

Your item has been added to the basket

You need to create an account, or login before you can add this item to your basket.